+86 15633683072

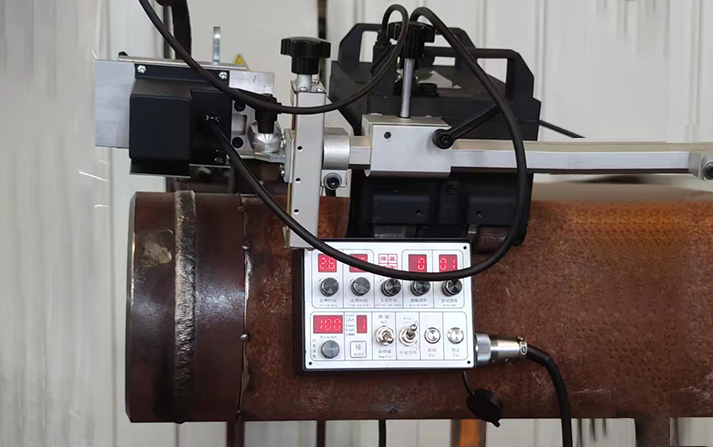

1. High Automation: A PLC intelligent control system enables fully automatic welding, reducing manual intervention and operator errors.

2. All-Position Welding Capability: The magnetic welding carriage can move 360° along the pipe, easily completing welds in any position.

3. Multi-Material Compatibility: It can weld a variety of metals, including carbon steel, stainless steel, and alloy steel.

4. High Stability and Repeatability: The built-in OSC (Operation Control) and AVC (Automatic Voltage Control) arc voltage control systems ensure beautiful and uniform welds.

5. High Productivity: Efficiency is 2-3 times that of traditional manual MIG welding, significantly saving labor and time.

| Tube Out Diameter | ≥140mm (≥5 inch) |

| Tube thickness | 4-60mm |

| Power brand | Kemppi HiArc 500A |

| Voltage (3-Phases 50/60Hz) | 380±10% 3 phases 50/60Hz |

| Rated Power | 60% 24.5KVA |

| 100% 17KVA | |

| Output 40℃ | 500A / 39.0V |

| 390A / 33.5V | |

| Fuse | 35A |

| Filler Wire Speed | 0~1500mm/min |

| Welding range | 13-50V |

| Size(L*W*H) of power source | 716*385*485mm |

| Weight of power source | 41 kg |

| Total Weight | 90 kg |

| Electromagnetic compatibility | A |

| Protection grade | IP23S |

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com